Aerospace Manufacturer Takes Off After Moving to the Cloud

Enjet Aero manufactures precision machined and fabricated components and assemblies for jet engines. With 9 manufacturing locations a centralized engineering and programming team, finding an integrated operating system was critical for efficiency and expansion. Ironically, they found it in the cloud(s).

Headquartered in Kansas, Enjet Aero has facilities in 9 U.S. locations, including this one in Washington, MO.

A recent Aerospace and Defense Industry Outlook predicted that the vertical will focus on innovation to improve efficiencies and reduce costs while taking advantage of growth opportunities. One company already accelerating on that runway is Enjet Aero, a precision machined and fabricated component manufacturer for commercial and military aircraft engine OEMs. The company has 650 employees and runs eight manufacturing locations plus headquarters and engineering support sites.

To be successful within their industry, Enjet Aero needs to manage a complex supply chain and inventory consisting of tens of thousands of parts and materials, and in an efficient manner, coordinate its manufacturing processes, many of which are multi-step and involve shipping products in various stage of development from one plant to another.

Further compounding Enjet Aero's complexity is the fact that they have completed eight acquisitions over the last six years and each of the companies they acquired utilized different software solutions to run their operations.

With a high-octane acquisition growth strategy, managing disparate systems can quickly become a massive and complicated job. Nicholas Mueller, director of ERP systems at Enjet Aero explained, "At first, our approach was to let each company run its own system. However, by our third acquisition we realized we needed a deliberate go-forward plan. We were running Epicor Kinetic deployed on premise, and at the Epicor Insights conference, I learned more about Epicor Kinetic in the cloud multisite capabilities and the Epicor Kinetic roadmap. That was enough to give us the confidence to standardize on cloud across sites."

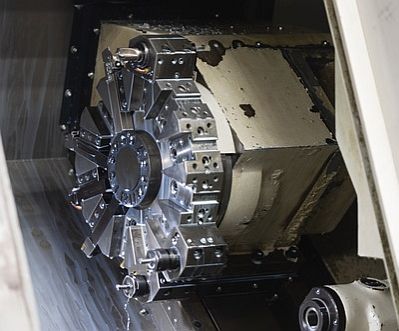

Enjet Aero machines, fabricates, forms, and delivers aircraft products.

The move to the cloud has been a game-changer for us. Within two days, I can have a have a new company set up and give it immediate access to everything Enjet. We can share data freely and get it up and running as a supplier to our other sites, which has alleviated supply chain issues, In addition, all sites are automatically updated to the latest version at the same time.

Enhanced Operations and Insights

The decision to regulate and standardize systems paid off in more than expected ways.

With a single integrated platform, Enjet Aero has effective information and resource sharing as well as consistent methods for scheduling, planning, purchasing and cross-site selling. Mueller disclosed, "We try to run as vanilla as possible, without a lot of customization. Getting everyone to use the same language and deploy consistent processes smooths communication, enabling us to identify potential issues, better understand KPIs across the business, and improve output to our customers."

Enjet Aero is 1 of 70,000 cloud manufacturing users.

As an example, one site might handle a project to supply another site. Instead of waiting for an email update on progress, the receiving site can simply log in and check the status -- a boost to operational efficiency.

Another crucial benefit is access to, control of, and confidence in business data.

"If we were looking at an increase in WIP or where inventory was not turning over, we all knew that it was an entity that was not yet on Epicor because divisions with it have the insights to enhance operations," Mueller acknowledged.

For a non-Epicor entity to achieve a pan-business view, data would be pulled from different systems, dumped into a spreadsheet, and there would be an attempt to aggregate it. Mueller admitted, "It was the proverbial apples and oranges. It simply could not be done in a scalable and time efficient way. Information is value, but it has a finite self-life. Once a certain amount of time passes the opportunity to realize the value of the information goes away. Now, with Epicor, we input information and it cascades through our sites and through our process, without loss of data and occurs in real time allowing us to react quickly to market changes and better serve our customers."

Enjet Aero specializes in manufacturing turbine and jet engine components.

Enjet Aero also tracks the exact same metrics across all locations, whether it's a high volume/low mix site or low volume/high mix, and BAQs (business activity queries) can instantaneously provide data for any and every site. Mueller shared, "Instead of spending time building the data, Epicor Kinetic enables us to invest our time analyzing it. The data enables us to build a plan to have the right parts on the shelf when a customer calls."

In addition, with Epicor Kinetic Financial Management, all accounting-related tasks are centralized, enabling sites to keep their focus on getting parts built for customers, not distracted with back-office functions.

Employees value Epicor Kinetic too. Mueller said, "There is often initial resistance because users of legacy software are both experts and proud of their systems. However, once they see Epicor in action, the fact that everything is right there -- MRP, scheduling, financials -- they love it!"

Cloud Accelerates Growth

More recently, significant industry disruptions -- including the COVID-19 pandemic -- slowed Enjet Aero's business. Instead of waiting for winds to shift, the company's leadership leveraged the quieter window to invest in becoming more agile.

The decision to move to the cloud as an effort by Enjet Aero to provide what their customers want -- a proactive, competent, responsive, and accountable partner as their supplier.

Mueller imparted, "Moving Epicor Kinetic to the cloud was very strategic to our business, both because of our acquisition strategy and also because we run a very lean IT team." He added, "We are not in the business of managing servers and storage. With everything in the cloud, we work in the system, not on managing it. We also value the security and disaster recovery aspects of cloud storage versus on premises servers."

Our leadership is continuously looking at how we can improve. Standardizing on Epicor, centralizing processes, and moving to the cloud have made us more agile, proactive and reliable.

Epicor Kinetic in the cloud accelerated Enjet Aero's acquisition strategy. The company has made three acquisitions since the pandemic.

"The move to the cloud has been a game-changer for us. Within two days, I can have a new company set up and give it immediate access to everything Enjet. We can share data freely and get it up and running as a supplier to our other sites, which has alleviated supply chain issues, In addition, all sites are automatically updated to the latest version at the same time," Mueller elaborated.

In the latest acquisition, he and his team brought the new company fully live in 90 days from the date the acquisition closed.

Committed to Non-Stop Improvement

The next part of the business to reap the benefits of process enhancement is content management.

Taking advantage of Industry 4.0 technology, Epicor Kinetic was designed with decades of manufacturing expertise to maximize revenue with advanced project and production management.

Mueller said, "We deployed Enterprise Content Management (ECM), but got sidetracked by an acquisition. It's a major focus for us now. We want to adopt the workflows to streamline approval processes and ensure compliance with government mandates such as CMMC (Cybersecurity Maturity Model Certification) and ITAR (International Traffic in Arms Regulations). Beyond that there are tremendous efficiency gains by linking documents to the ERP for one click retrieval such as suppliers NDA's, customer PO's, shipping documents, and others. It displaces a lot of filing cabinets and network storage."

Investing to maintain an unwavering focus on core business optimization and consistent customer satisfaction has enabled Enjet Aero to continue to expand. Mueller noted, "Our leadership is continuously looking at how we can improve. Standardizing on Epicor, centralizing processes, and moving to the cloud have made us more agile, proactive and reliable."

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::